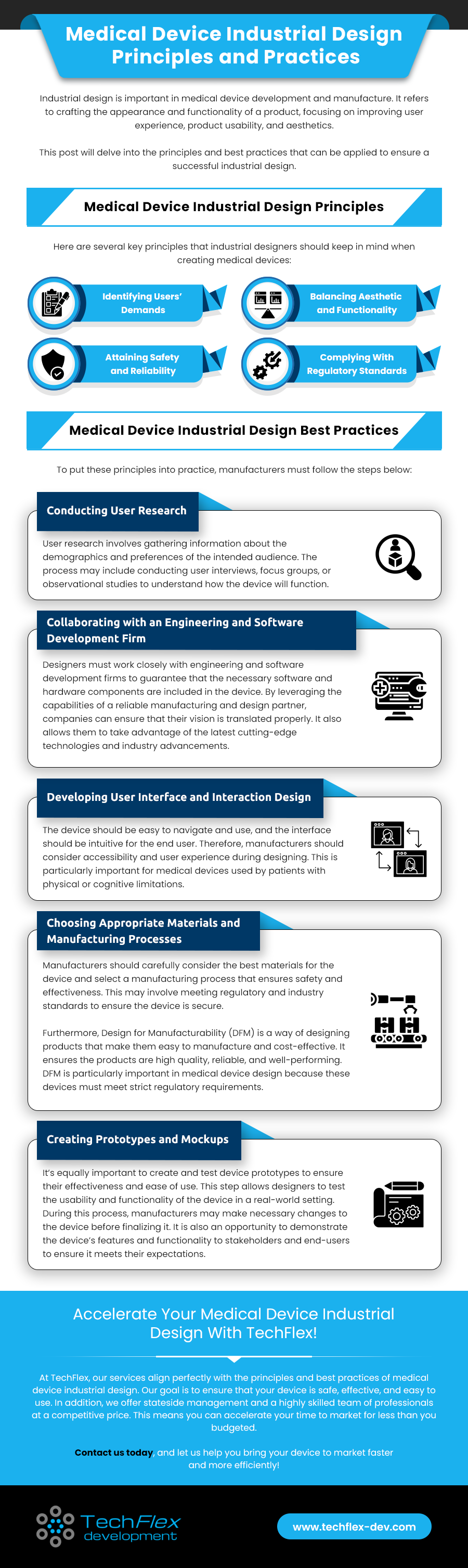

Medical Device Industrial Design Principles and Practices

Industrial design is important in medical device development and manufacture. It refers to crafting the appearance and functionality of a product, focusing on improving user experience, product usability, and aesthetics.

This post will delve into the principles and best practices that can be applied to ensure a successful industrial design.

Medical Device Industrial Design Principles

Here are several key principles that industrial designers should keep in mind when creating medical devices:

Identifying Users’ Demands

This entails thorough research to learn about the user’s expectations and preferences. By knowing the user’s perspective, designers can deliver devices that meet their needs.

Balancing Aesthetic and Functionality

Products must not only fulfill their intended function but also have a neat and appropriate design. Medical equipment is sometimes complicated to operate, so designers must strive to make them as intuitive and user-friendly as possible.

Attaining Safety and Reliability

Manufacturers should pay close attention to every element of the device’s design, production, and quality control procedures to create precisely engineered medical equipment.

Complying With Regulatory Standards

Some regulations and guidelines govern medical devices. Therefore, manufacturers are responsible for ensuring their products meet these specifications. To do this, they must stay updated on the rules and regulations and consider them when designing.

Medical Device Industrial Design Best Practices

To put these principles into practice, manufacturers must follow the steps below:

Conducting User Research

User research involves gathering information about the demographics and preferences of the intended audience. The process may include conducting user interviews, focus groups, or observational studies to understand how the device will function.

1

Collaborating With an Engineering and Software Development Firm

Designers must work closely with engineering and software development firms to guarantee that the necessary software and hardware components are included in the device. By leveraging the capabilities of a reliable manufacturing and design partner, companies can ensure that their vision is translated properly. It also allows them to take advantage of the latest cutting-edge technologies and industry advancements.

2

Developing User Interface and Interaction Design

The device should be easy to navigate and use, and the interface should be intuitive for the end user. Therefore, manufacturers should consider accessibility and user experience during designing. This is particularly important for medical devices used by patients with physical or cognitive limitations.

3

Choosing Appropriate Materials and Manufacturing Processes

Manufacturers should carefully consider the best materials for the device and select a manufacturing process that ensures safety and effectiveness. This may involve meeting regulatory and industry standards to ensure the device is secure.Furthermore, Design for Manufacturability (DFM) is a way of designing products that make them easy to manufacture and cost-effective. It ensures the products are high quality, reliable, and well-performing. DFM is particularly important in medical device design because these devices must meet strict regulatory requirements.

4

5. Creating Prototypes and Mockups

It’s equally important to create and test device prototypes to ensure their effectiveness and ease of use. This step allows designers to test the usability and functionality of the device in a real-world setting. During this process, manufacturers may make necessary changes to the device before finalizing it. It is also an opportunity to demonstrate the device’s features and functionality to stakeholders and end-users to ensure it meets their expectations.

5

Accelerate Your Medical Device Industrial Design With TechFlex!

At TechFlex, our services align perfectly with the principles and best practices of medical device industrial design. Our goal is to ensure that your device is safe, effective, and easy to use. In addition, we offer stateside management and a highly skilled team of professionals at a competitive price. This means you can accelerate your time to market for less than you budgeted.

Contact us today, and let us help you bring your device to market faster and more efficiently!