I meet with medical device entrepreneurs every week who tell me about their “amazing” team. When I ask about their backgrounds, the conversation usually goes like this:

“Our CTO is brilliant—he’s working for equity because he really believes in the vision. Our regulatory consultant is doing it for a small fee plus equity. Our mechanical engineer is a recent grad who’s excited to learn on the job for equity.”

My heart sinks every time I hear this because I know what’s coming next: missed deadlines, quality issues, expensive mistakes, and ultimately a much higher cost than if they’d just hired experienced professionals from the start.

The equity trap is one of the most seductive and dangerous mistakes in medical device development. It feels smart—you’re conserving cash and building a committed team. In reality, you’re often trading short-term cash savings for long-term disasters that cost far more than market-rate salaries ever would.

The Hidden Math of “Free” Labor

Let’s start with the brutal economics. When someone works for equity instead of salary, they’re not working for free—they’re working for deferred, uncertain compensation. This creates misaligned incentives that manifest in predictable ways.

Here’s what the math actually looks like:

Market Rate Professional ($120K annually):

- Delivers on time and on budget

- Requires minimal oversight

- Makes fewer costly mistakes

- Total cost: $120K

Equity-Only Worker ($0 cash):

- Takes 50% longer due to inexperience

- Requires constant management oversight

- Makes expensive design mistakes requiring rework

- Creates regulatory compliance issues

- Hidden cost: $240K+ (2x market rate)

The problem isn’t that equity workers are incompetent—it’s that people available to work for equity often lack the specific experience your medical device project demands.

Why the Best People Aren’t Available for Equity

Think about this logically: if someone is truly expert at medical device development, why would they work for equity instead of their market rate?

Experienced professionals have alternatives:

- They can command market rates elsewhere

- They have mortgages, families, and financial obligations

- They’ve seen enough startups fail to know equity is risky

- They value their time and expertise appropriately

People available for equity typically fall into these categories:

- Recent graduates with no industry experience

- Career changers learning new fields

- Between jobs and looking for opportunities

- Retired professionals seeking part-time engagement

- True believers in your specific vision (rare)

None of these categories are inherently bad, but they create predictable risks in medical device development.

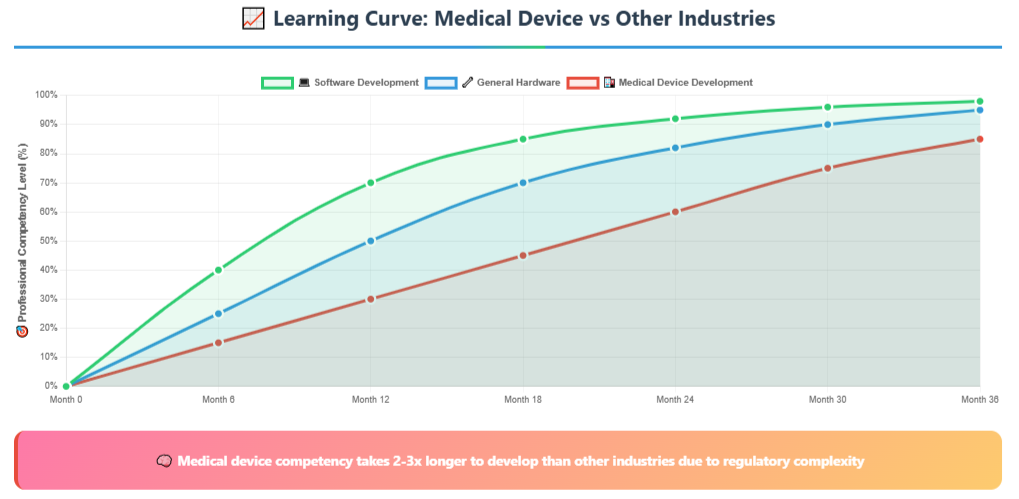

The Experience Gap in Medical Devices

Medical device development isn’t like building a mobile app where you can “move fast and break things.” The regulatory environment, safety requirements, and technical complexity demand specific experience that can’t be learned on the job without significant cost.

Why medical devices are different:

Regulatory Complexity: Understanding FDA requirements, design controls, risk management, and quality systems takes years to master. A mistake here can delay your project by 12+ months.

Safety-Critical Design: Unlike consumer products, medical device failures can injure or kill people. This requires conservative engineering approaches and extensive validation.

Integration Challenges: Medical devices must integrate with hospital systems, EMRs, and clinical workflows. Understanding these ecosystems requires experience.

Manufacturing Constraints: Transitioning from prototype to manufacturing involves unique challenges in medical devices, from sterilization to biocompatibility.

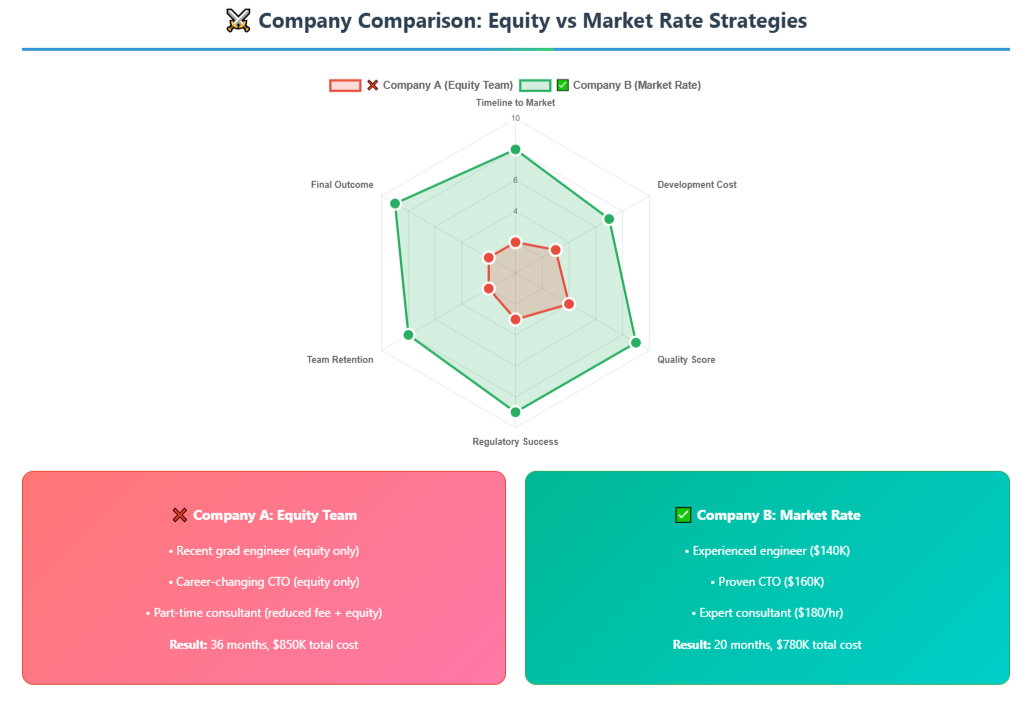

Case Study: Two Companies, Two Approaches

Let me tell you about two companies I worked with, both developing cardiac monitoring devices with similar funding and timelines.

Company A: The Equity Approach

- Team: Recent grad engineer (equity), career-changing CTO (equity), part-time regulatory consultant (reduced fee + equity)

- Initial cash burn: $8K/month

- Timeline: 36 months to first customer (planned: 18 months)

- Total cost: $850K (planned: $400K)

- Outcome: Finally launched but with limited market success due to design compromises

Company B: The Market Rate Approach

- Team: Experienced medical device engineer ($140K), proven CTO ($160K), expert regulatory consultant ($180/hour)

- Initial cash burn: $35K/month

- Timeline: 20 months to first customer

- Total cost: $780K

- Outcome: Successful launch, acquired for $15M after 2 years

The surprising result: Company B spent less money overall and achieved a much better outcome, despite higher monthly costs.

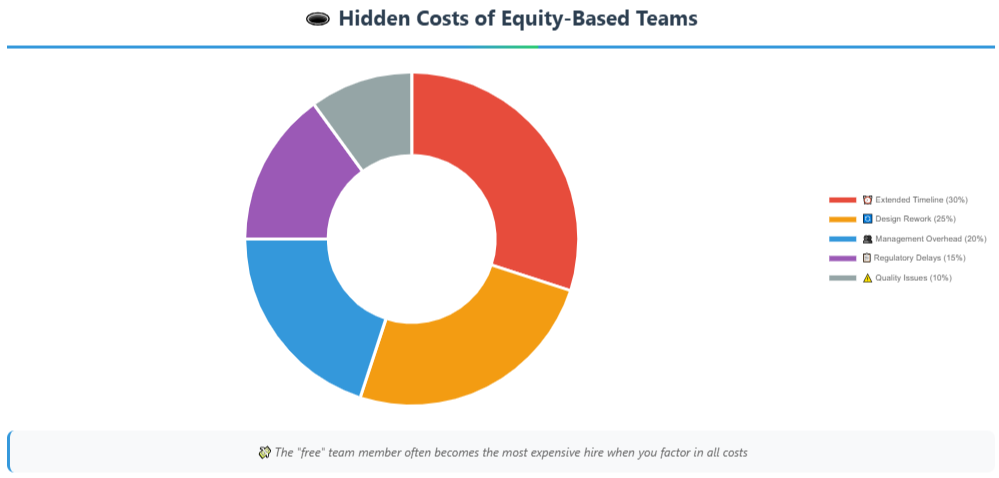

The Hidden Costs of Equity Teams

The apparent savings of equity workers disappear when you account for the hidden costs:

- Extended Timeline (30% of hidden costs)

Inexperienced team members take longer to complete tasks. What should take 2 weeks takes 4 weeks. In medical device development, time is extremely expensive because:

- You’re burning cash monthly with no revenue

- Market opportunities disappear

- Competitors gain advantages

- Investor confidence erodes

- Design Rework (25% of hidden costs)

Inexperienced engineers make design decisions that seem reasonable but create problems later:

- Choosing components that can’t be sterilized

- Creating designs that can’t be manufactured cost-effectively

- Missing EMC requirements that require complete PCB redesign

- Overlooking usability issues discovered in clinical testing

- Management Overhead (20% of hidden costs)

Equity workers require much more management:

- Constant mentoring and guidance

- Detailed review of all work products

- Frequent course corrections

- Team coordination challenges

- Regulatory Delays (15% of hidden costs)

Regulatory mistakes are extremely expensive:

- FDA rejection requiring complete resubmission

- Missing design control documentation

- Inadequate risk analysis requiring study updates

- Clinical protocol errors extending trial timelines

- Quality Issues (10% of hidden costs)

Poor initial quality creates cascading problems:

- Field failures requiring recalls

- Customer support burden

- Reputation damage affecting sales

- Additional validation testing

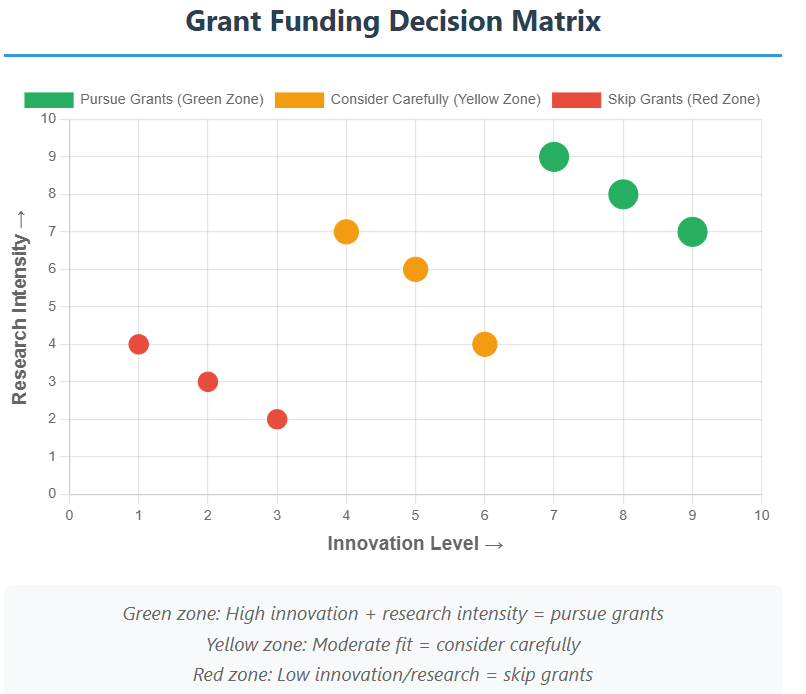

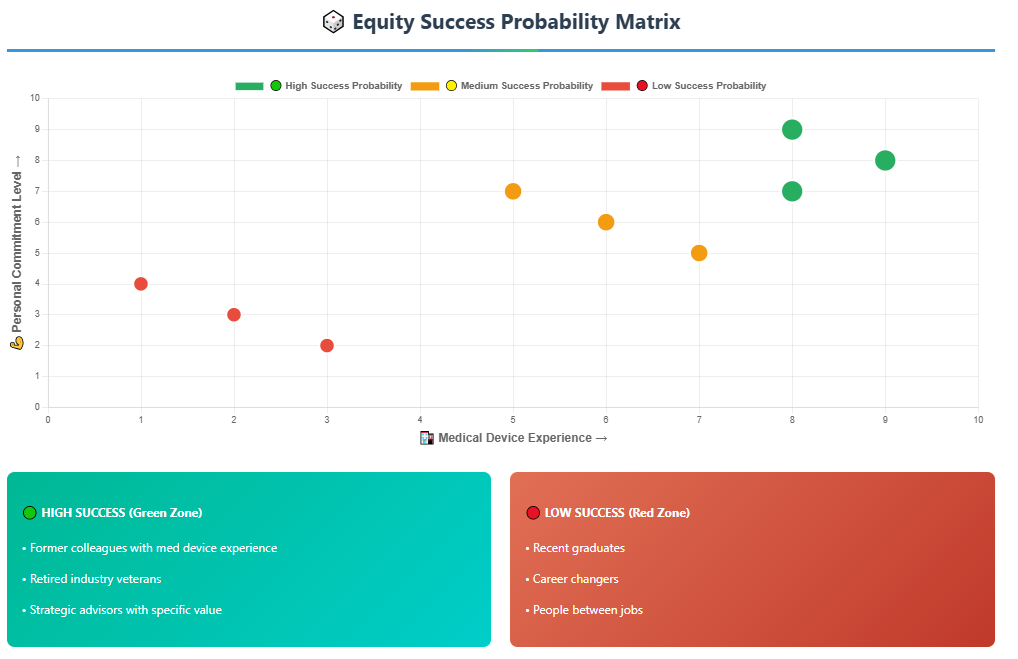

When Equity Actually Makes Sense

I’m not completely anti-equity. There are specific circumstances where equity arrangements can work:

Green Zone – Equity Can Work:

- Former colleagues with proven medical device experience

- Retired industry veterans seeking engagement

- Strategic advisors bringing specific value beyond labor

- Co-founders with complementary expertise

Yellow Zone – Proceed Carefully:

- Experienced freelancers between projects

- Part-time consultants with relevant experience

- Serial entrepreneurs with some medical device background

Red Zone – Avoid Equity:

- Recent graduates without industry experience

- Career changers learning medical device development

- People between jobs seeking any opportunity

- Anyone without specific medical device expertise

The Smart Equity Strategy

If you do use equity, structure it intelligently:

- Hybrid Compensation

Never go pure equity. Pay at least 50-70% of market rate in cash, with equity as an upside bonus. This ensures people can pay their bills and aren’t desperate.

- Performance Milestones

Tie equity vesting to specific deliverables and timelines. If someone takes twice as long as expected, their equity should reflect that.

- Expertise Premium

Pay more (in cash) for critical expertise like regulatory affairs or clinical development. These skills are too important to gamble on.

- Time Limits

Set clear timelines for converting to market-rate salaries. Plan to eliminate equity-only positions within 12-18 months.

The Alternative: Strategic Hiring

Instead of building a full team immediately, consider this approach:

Phase 1: Core Team (Months 1-6)

- You + 1-2 market-rate experts in critical areas

- Use contractors for specialized needs

- Validate core concepts before scaling

Phase 2: Targeted Expansion (Months 7-12)

- Add 2-3 key hires based on validated needs

- Mix of full-time and contractors

- Pay market rates for critical skills

Phase 3: Scale Team (Months 13+)

- Build full team once revenue/funding is secured

- Use early success to attract top talent

- Negotiate from strength, not desperation

The Bottom Line

“Working for equity” isn’t free labor—it’s expensive, risky labor that appears cheap until you account for the hidden costs. In medical device development, where mistakes are costly and expertise is critical, the equity trap can destroy your company.

The math is clear: paying market rates for experienced professionals usually costs less than the hidden expenses of inexperienced equity workers. More importantly, experienced professionals dramatically increase your chances of success.

Remember: if someone truly excellent is available to work for equity, ask yourself why. The answer is usually either they’re not as excellent as they seem, or there are circumstances (like personal relationships or strategic interests) that make your situation unique.

In our next article, we’ll explore the manufacturing money pit—why completing your design is just the beginning of your spending, not the end.